Today, Emanuel’s model is not only used in the teaching he does in his new positions as a Method Expert in X-ray and Neutron Imaging at the Division of Solid Mechanics and as an Application Expert in Tomographic Imaging and Image Analysis at LUNARC, the Center for Scientific and Technical Computing at Lund University, it is also used as a prototype for the test beamline YMIR for the future imaging beamline ODIN, which will be built at ESS. This is because the techniques employed in the model can be used to test both hardware and software pipelines both with light tomography and neutron tomography – even though Emanuel’s model fits on two tables, and a neutron beamline fits in a very large room!

Samuel Staines, a master student at the Division of Solid Mechanics, is responsible for designing a replica of the model which can be compatible with what is needed for the new YMIR test beamline and the future ODIN beamline at ESS. He explains that it works just as well to use normal light as it would to use neutrons in order to test out how the beamline might behave. Before the ODIN beamline is built, the techniques will be tested in the test beamline, YMIR.

– There is a huge amount of work you need to do to develop a new beamline. That is why you need to test the platform, including hardware and software pipelines in multiple ways. One way is to refine and test in a smaller scale to get ideas on where the challenges and pitfalls will lie with the new instrument, says Samuel Staines.

Improving data collection strategies

Stefanos Athanasopoulos, who is a Guest Researcher at the Division of Solid Mechanics is also involved in the project with ESS. His work is focused on improving the data collection strategies for future experiments at large scale research facilities.

– A big part of developing a new beamline is also about testing optimal ways for data collection. How will it actually work when a user comes in and runs an experiment? At the moment a lot of data is acquired from the experiments, says Stefanos Athanasopoulos.

– The ideal solution would be to build a single log file with all the data and information about the experimental setup so that you get everything in one place. That file can then be used by different researchers, not just the person conducting the actual experiments.

The model makes techniques available to more students

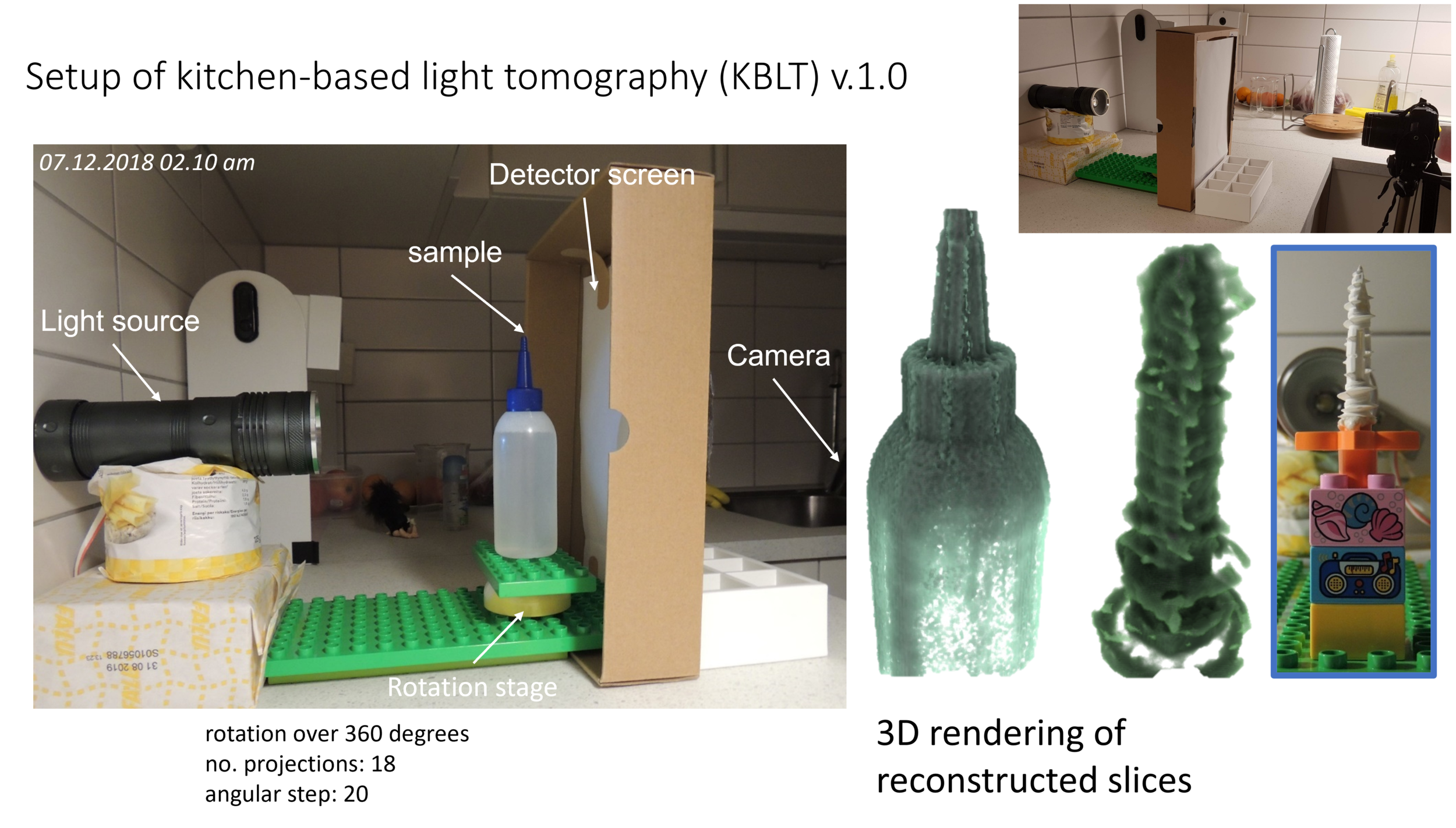

Emanuel Larsson is also planning to make the code of his model freely available to students across the world – with the help of LINXS and Stephen Hall, outgoing Director of LINXS, and Senior Lecturer at the Division of Solid Mechanics at LTH. The idea is to publish an article on the kitchen tomography lab scanner, along with making the code available to download from the platform GitHub. If this plan succeeds, the cost of teaching students tomography techniques can be reduced drastically. Today, x-ray tomography scanners in laboratories can cost between 40 k€ to 1 M€. In comparison, the kitchen tomography scanner model can be built with readily available materials for between 100€ to 1000€, depending on which version of the KBLT scanner the students would like to build.

– Hopefully, the model can help inspire more students to start using imaging techniques in their research early on. It allows them to play around with samples and sample environments – for example what will happen if you point a heat gun onto a rotating sample, and image the change in 3D over time, thus meaning 4D?

While using the model, students will also learn important skills in engineering, image reconstruction, analysis and 3D-rendering. Skills that will come in handy for future imaging experiments both at ESS and MAX IV.

– In a few years models like the kitchen tomography scanner could have huge impact in terms of increasing the user base of people using the techniques offered at large scale research facilities. It is all about inspiring people and making it easy to learn, test things and have fun at the same time, Emanuel Larsson concludes.

Researchers from ESS who are involved in the project

Kenan Murić, Data Acquisition Scientist, ESS.

Robin Woracek, Instrument Scientist, ESS.

Søren Schmidt, Senior Scientist, ESS.

Tobias Richter, Group Leader for Experiment Control and Data Curation, ESS.